WireTough delivers the highest impact strength in the class of light weight steel cylinders that are fiber-reinforced. WireTough tanks are certified to handle hydrogen and a wide range of non-corrosive gases, including CNG, nitrogen and compressed air.

WireTough’s hydrogen tanks are certified under ASME Section VIII, Division 3 and the additional requirements of KD-10, which impose specific requirements for hydrogen. WireTough offers tanks with capacities up to 47.7 Kg of hydrogen. WireTough tanks for hydrogen storage have especially long cycle lives because one of the steps in our manufacturing process, autofrettaging, improves the tanks’ resistance to hydrogen embrittlement and cracking.

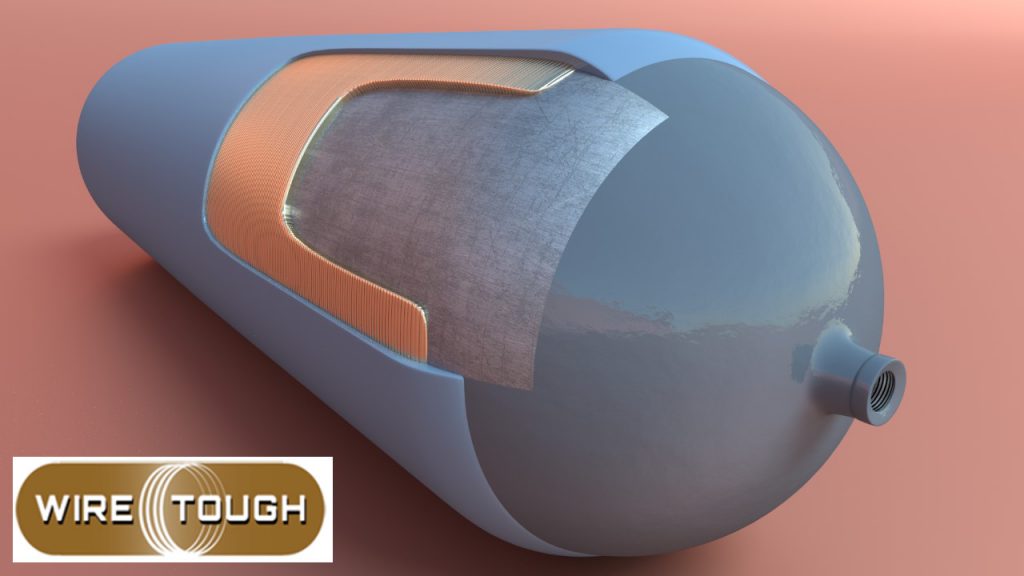

WireTough’s breakthrough is the result of its’ innovative and proprietary production technology, where lightweight steel liners are wrapped with very high strength steel wire, sealed with a special epoxy and covered with a protective, UV resistant coating. Because they dissipate heat more rapidly than Type III and IV tanks, WireTough Type II cylinders can hold 20-30% more CNG under fast fill than Type IV tanks, They are about 20% lighter than all steel Type I cylinders of equivalent capacity and pressure rating. Subjected to the rigorous NGV-2 tests, WireTough tanks meet and exceed ANSI-NGV-2-2007 and US-DOT requirements. Our tank design for ground storage of gases also meets ASME Section VIII Division 3 requirements. The technology is protected by US patents and applications for patents.

The superiority of the Company’s technology was recognized by the US Department of Energy (DOE) which, in 2014, awarded a $2.4 million grant to WireTough to develop low cost hydrogen storage. The company successfully completed that program, after meeting the pressure and cost targets set by DOE.

WireTough tanks have significant advantages over Type II tanks that are reinforced with carbon fiber. First, there is a cost advantage since steel wire is much less expensive than carbon fiber. While all cylinders in the market meet the DOT and NGV-2 minimum requirements, there is a distinctive difference between the designs. When safety is the most important element of the structure, all steel structure provides several advantages. WireTough Cylinders’ structural integrity does not rely upon epoxy for its strength. It continues to provide reliable structural behavior well above 160C (320F) when most fiber-epoxy composites lose usable strength. For over four minutes after the Bonfire test where surface temperatures exceeded 538 C (1,000F), WireTough’s cylinder remained intact and maintained its structural integrity. An independent laboratory conducted a special test of WireTough Cylinders outside the usual DOT and NGV-2 requirements. The surface of the tank was exposed to salt water and the tank was cycle tested (filled and emptied) 3000 times to cause expansion and contraction. The cylinder passed the test and no long-range damage due to saltwater was observed.