WireTough Cylinders, LLC produces pressure vessels for hydrogen storage at pressures ranging from 50 to 87.5 MPa (500 to 875 bar). At these higher pressures, WireTough’s wire-wrapped technology has a distinct advantage because it can offer far longer service life and durability at a very competitive price. We have designated our cylinders as Type II-S to differentiate them from Type II cylinders wrapped with fiberglass or carbon fiber. The potential uses for these pressure vessels are:

- Fueling stations for light vehicles, such as cars and light trucks. This market is projected to grow rapidly.

- Fueling stations for heavy duty vehicles. The market for 18-wheel trucks and buses is emerging; Nikola’s goals in that regard will be transformative. They plan to begin producing trucks in 2022 and build 100 hydrogen fueling stations per year from 2022 through 2028.

- There are companies that manufacture fuel cells for standby power generation such as GenCell and Hydrogenics. This market has been historically growing.

- Hydrogen is being used to power a wide range of other vehicles. For example, Plug Power has 13,000 forklifts running on fuel cells in a market that is also expanding.

- Excess power produced during peak periods from renewable energy sources and during lean demand periods can be stored by generating hydrogen for use during high demand periods.

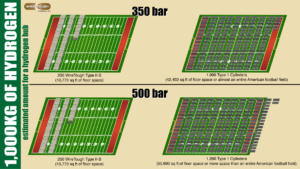

- Shell Oil has committed to build 50 new fueling stations in Southern California in the next 5 years. Each station will require a ground storage capacity of 600 KG of hydrogen.

- European companies such as H2B2, Haskell, and FTI have ambitious plans to expand in the US.

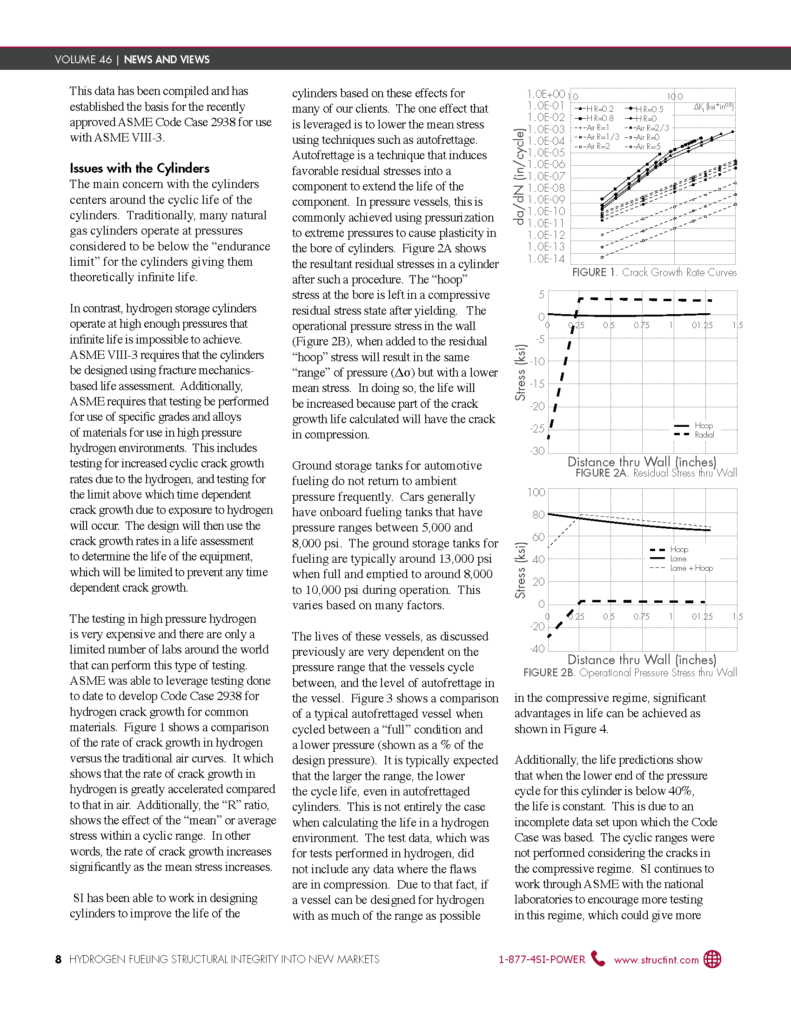

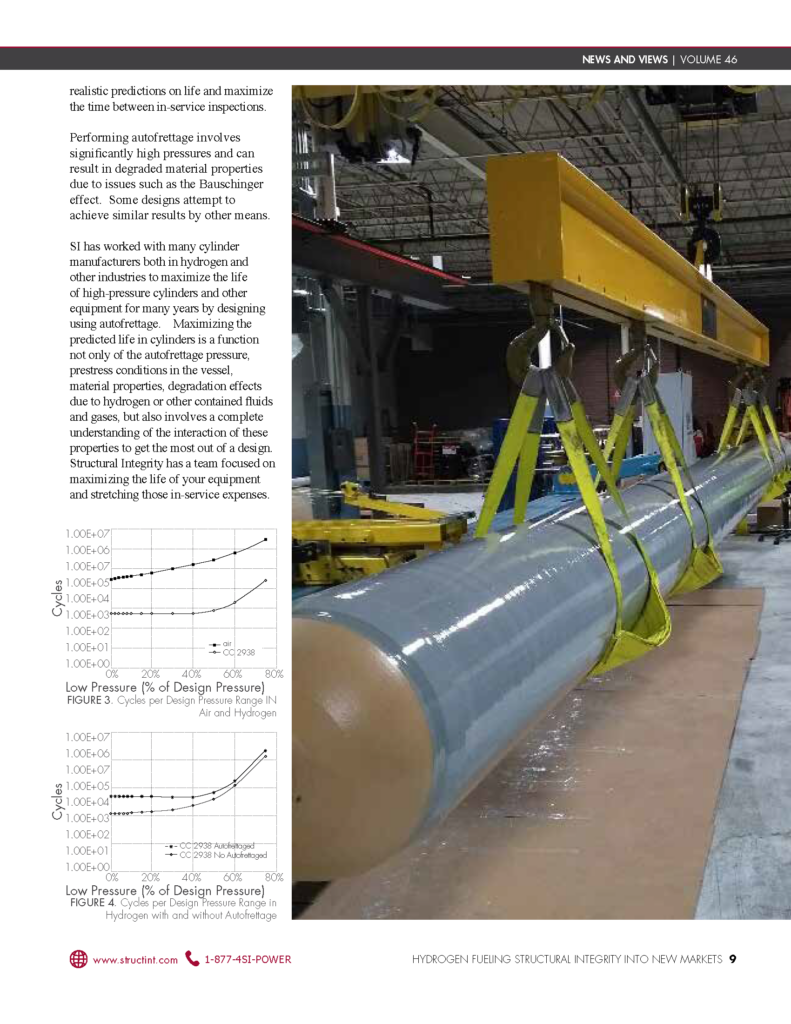

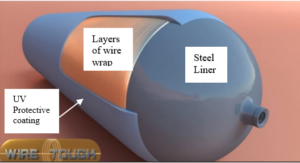

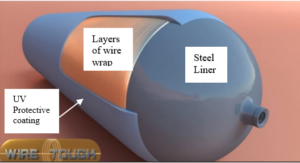

WireTough’s Type II-S cylinder design uses a commercially available steel liner that is wrapped with several layers of off-the-shelf, very high strength steel wire filaments, held together by epoxy.  WireTough’s technology is patented and proprietary. The high ductility of steel wires (>15%) in the wrap allows the cylinders to be pressurized to greater than two-times their maximum allowable pressure during the manufacturing process. This over-pressurization process is called “autofrettage” and it causes plastic flow in the liner and locks high compressive stresses in the entire cross-section of the liner that enhances the tank’s fatigue cyclic life during service. This is a key issue in storing corrosive gases like hydrogen.

WireTough’s technology is patented and proprietary. The high ductility of steel wires (>15%) in the wrap allows the cylinders to be pressurized to greater than two-times their maximum allowable pressure during the manufacturing process. This over-pressurization process is called “autofrettage” and it causes plastic flow in the liner and locks high compressive stresses in the entire cross-section of the liner that enhances the tank’s fatigue cyclic life during service. This is a key issue in storing corrosive gases like hydrogen.

The primary competing technology, steel liners wrapped with carbon fiber, is limited in its’ ability to sustain high autofrettage pressures because the carbon fiber filaments have low ductility (≤ 0.5%). Because carbon fiber wrapped cylinders cannot be pressurized as much during the manufacturing process, they do not bring the benefits of long cycle life that WireTough’s tanks do.

The manufacturing processes and design feasibility of steel wire-wrapped cylinders has been demonstrated as part of a Department of Energy (DOE) sponsored project executed by WireTough for cylinders with a maximum operating pressure of 875 bar. WireTough has obtained certification under ASME Boiler and Pressure vessel Code (BPVC) Section VIII-Division 3 for its design.

Type II-S wire-wound steel cylinders, first introduced in 2011 for onboard CNG storage tanks in vehicles, have superior resistance to impacts and ballistics and fire. The cylinders tested were made from 0.25” thick wall liners and contained only 8 layers of wire. The hydrogen cylinders utilize liners > 1.0” thick wall and 20 layers of steel wire and will therefore have much higher impact and ballistic resistance. Extensive testing was conducted to demonstrate WireTough’s superior resistance to impact, ballistics, salt water corrosion resistance and fire.

Environment Assisted Cracking (EAC) is a major design concern when working with high strength, quenched and tempered ferritic steels used in pressure vessels for storing hydrogen. The Type II-S cylinders have been designed with EAC as the main design criterion. ASME Boiler and Pressure Vessel Code Committee has recognized this and has proposed rules under its Division 3 that are based on fracture mechanics, an approach ideally suited for considering EAC as an integral part of the design process. WireTough’s Type II-S pressure vessel has been designed in accordance with this ASME Code.

WireTough’s bullet test cylinder proved to be very robust, deflecting .30 cal. bullet fire and only being penetrated when hit with a .50 cal. BMG round and even that penetration could not continue through the other side.

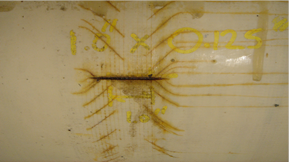

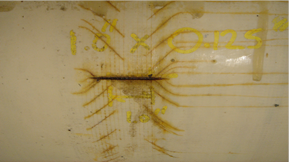

The exterior surface condition of the Type II-S cylinder after a bonfire test showing that the steel wrap was still intact.

Exterior surface of the Type II-S tank after exposure to salt water for 28 days while being cycled for 3,200 cycles.

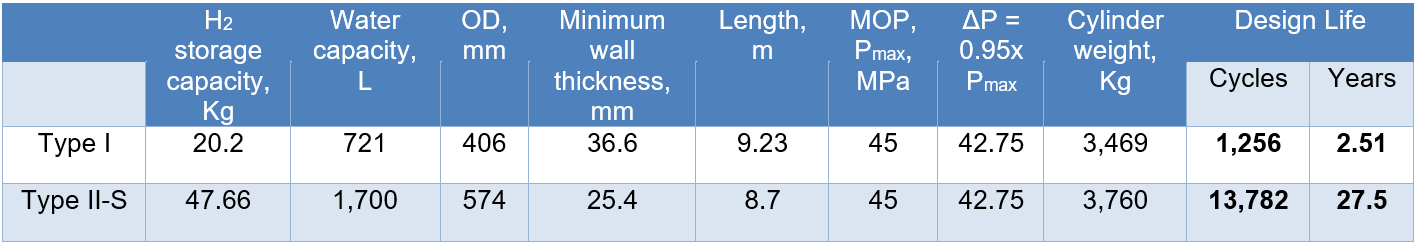

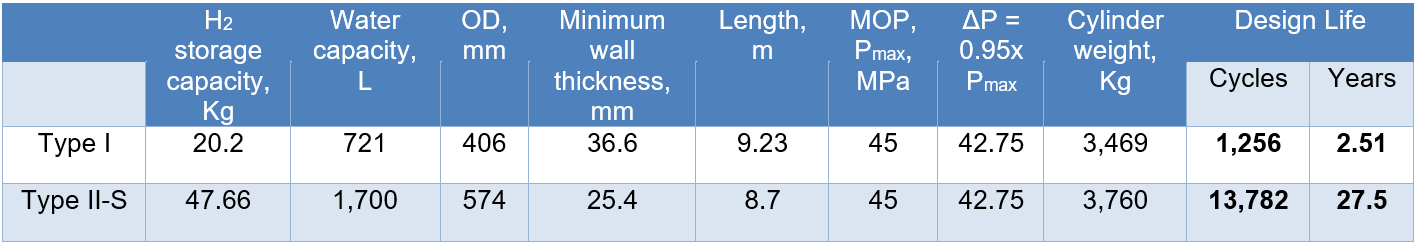

The Table below provides comparisons of design lives estimated using the ASME Section VIII-Division 3 recommended procedures for service in hydrogen. Life and storage capacities of Type I cylinders rated for 45 MPa pressure and WireTough’s Type II-S cylinders of comparable weights are compared.

Design Lives and Capacity of Type I and Type II-S Cylinders

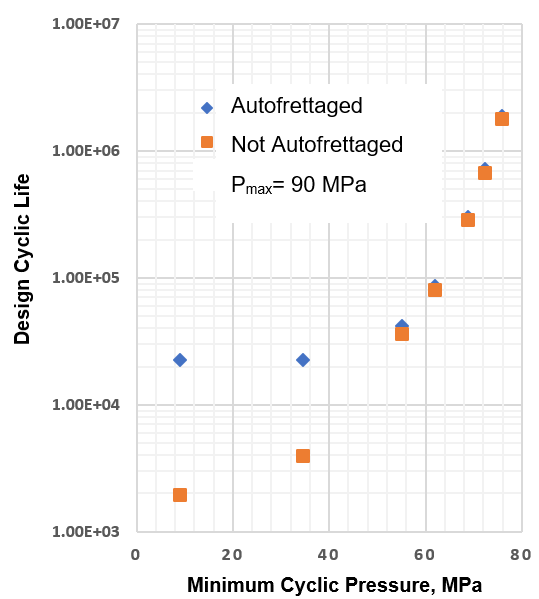

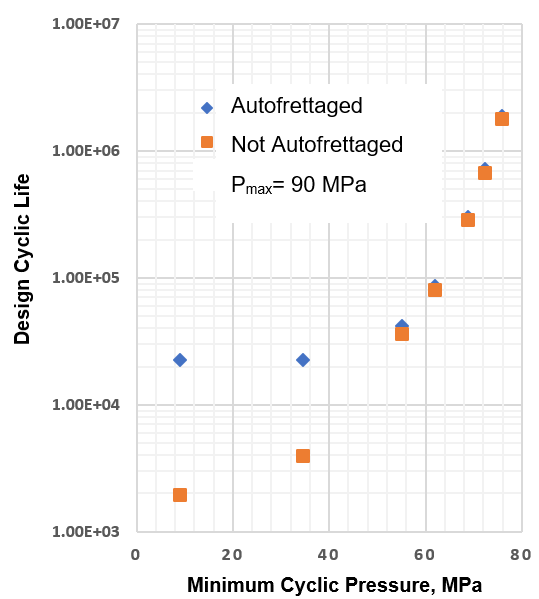

Autofrettage plays an important role in boosting the design life of hydrogen storage vessels during deep pressure cycling. Some cylinders in a cascade will experience deep cycles in which the pressures will fluctuate between the maximum operating pressure, Pmax, and a minimum pressure that can be as low as 5 to 10% of Pmax. For Pmax of 90 MPa, the life of autofrettaged cylinders are estimated to be several times higher than cylinders that are not autofrettaged.

Autofrettage plays an important role in boosting the design life of hydrogen storage vessels during deep pressure cycling. Some cylinders in a cascade will experience deep cycles in which the pressures will fluctuate between the maximum operating pressure, Pmax, and a minimum pressure that can be as low as 5 to 10% of Pmax. For Pmax of 90 MPa, the life of autofrettaged cylinders are estimated to be several times higher than cylinders that are not autofrettaged.

WireTough’s technology is patented and proprietary. The high ductility of steel wires (>15%) in the wrap allows the cylinders to be pressurized to greater than two-times their maximum allowable pressure during the manufacturing process. This over-pressurization process is called “autofrettage” and it causes plastic flow in the liner and locks high compressive stresses in the entire cross-section of the liner that enhances the tank’s fatigue cyclic life during service. This is a key issue in storing corrosive gases like hydrogen.

WireTough’s technology is patented and proprietary. The high ductility of steel wires (>15%) in the wrap allows the cylinders to be pressurized to greater than two-times their maximum allowable pressure during the manufacturing process. This over-pressurization process is called “autofrettage” and it causes plastic flow in the liner and locks high compressive stresses in the entire cross-section of the liner that enhances the tank’s fatigue cyclic life during service. This is a key issue in storing corrosive gases like hydrogen.

Autofrettage plays an important role in boosting the design life of hydrogen storage vessels during deep pressure cycling. Some cylinders in a cascade will experience deep cycles in which the pressures will fluctuate between the maximum operating pressure, Pmax, and a minimum pressure that can be as low as 5 to 10% of Pmax. For Pmax of 90 MPa, the life of autofrettaged cylinders are estimated to be several times higher than cylinders that are not autofrettaged.

Autofrettage plays an important role in boosting the design life of hydrogen storage vessels during deep pressure cycling. Some cylinders in a cascade will experience deep cycles in which the pressures will fluctuate between the maximum operating pressure, Pmax, and a minimum pressure that can be as low as 5 to 10% of Pmax. For Pmax of 90 MPa, the life of autofrettaged cylinders are estimated to be several times higher than cylinders that are not autofrettaged.